Used meat rail systems are taking the meat processing industry by storm, offering a cost-effective and environmentally friendly solution for businesses. This guide delves into the types, benefits, considerations, and maintenance of used meat rail systems, empowering you to make informed decisions and elevate your operations.

With their versatility and proven effectiveness, used meat rail systems cater to a wide range of industries, from small-scale butchers to large-scale processing plants. Their ability to streamline processes, reduce costs, and promote sustainability makes them an indispensable tool for modern meat processing.

Market Analysis

The global used meat rail systems market is projected to reach USD 1.5 billion by 2027, growing at a CAGR of 4.5% during the forecast period. The increasing demand for meat products, coupled with the rising adoption of automation in the meat processing industry, is driving the market growth.

Key Market Trends and Growth Drivers

- Rising demand for meat products

- Increasing adoption of automation in meat processing

- Growing emphasis on cost-effectiveness

- Government regulations on food safety

Competitive Landscape and Major Players

The competitive landscape of the used meat rail systems market is fragmented, with several key players operating in the market. Some of the major players include:

- JBT Corporation

- Marel

- Interroll

- Dematic

- Vanderlande

Types of Used Meat Rail Systems

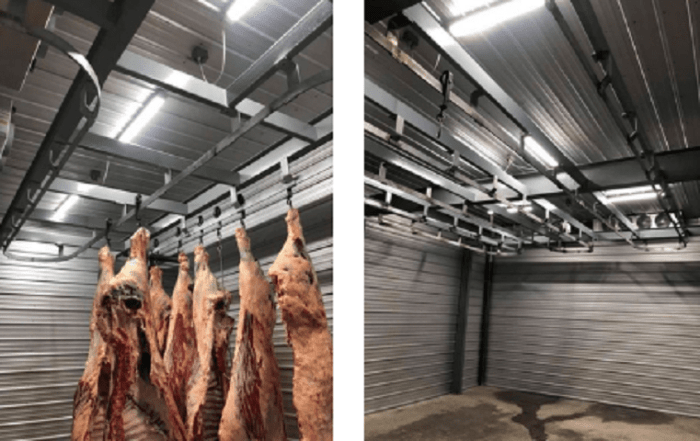

Overhead Rail Systems

Overhead rail systems are suspended from the ceiling and provide a flexible and efficient way to transport meat products throughout the processing facility. They are ideal for facilities with limited floor space and high ceilings.

Floor Rail Systems

Floor rail systems are installed on the floor and provide a more cost-effective option compared to overhead systems. They are commonly used in smaller facilities or for specific processes, such as cutting and packaging.

Conveyor Rail Systems

Conveyor rail systems combine the features of overhead and floor systems, providing a continuous flow of meat products. They are ideal for facilities with high production volumes and require a high degree of automation.

Benefits of Using Used Meat Rail Systems

Cost Savings

Used meat rail systems can provide significant cost savings compared to purchasing new systems. They are often available at a fraction of the cost of new equipment, making them an attractive option for businesses with limited budgets.

Environmental Advantages

Reusing used meat rail systems contributes to environmental sustainability by reducing waste and conserving resources. It also helps to extend the lifespan of equipment, reducing the need for frequent replacements.

Proven Performance

Used meat rail systems have been thoroughly tested and proven to perform reliably. They are often backed by warranties and have a long track record of successful operation.

Considerations for Purchasing Used Meat Rail Systems

Inspect Equipment Before Purchase

Thoroughly inspect the equipment before making a purchase to assess its condition and identify any potential issues. Check for any signs of damage, corrosion, or wear and tear.

Negotiate the Best Price

Negotiate the best possible price by comparing quotes from multiple suppliers and considering the condition of the equipment, its age, and any additional features or accessories included.

Check Warranty and Support

Inquire about the warranty and support available for the used meat rail system. This will provide peace of mind and ensure that you have access to assistance if any issues arise.

Installation and Maintenance of Used Meat Rail Systems

Installation

- Prepare the site by ensuring a level and stable surface.

- Assemble the rail system according to the manufacturer’s instructions.

- Connect the system to the power supply and any other necessary utilities.

- Test the system to ensure proper operation.

Maintenance

| Routine Maintenance | Frequency |

|---|---|

| Clean and lubricate moving parts | Monthly |

| Inspect rails for damage | Quarterly |

| Tighten bolts and connections | Semi-annually |

Safety Precautions, Used meat rail systems

- Wear appropriate safety gear, including gloves and safety glasses.

- Keep hands and clothing away from moving parts.

- Follow all manufacturer’s instructions for safe operation and maintenance.

FAQ Section

What are the main types of used meat rail systems?

Used meat rail systems come in various types, including overhead systems, floor systems, and conveyor systems, each with its own advantages and applications.

How can used meat rail systems save me money?

Purchasing used meat rail systems can significantly reduce upfront costs compared to new systems, allowing businesses to allocate funds to other areas of their operations.

Are there any environmental benefits to using used meat rail systems?

Yes, reusing equipment reduces waste and promotes sustainability by extending the lifespan of materials and reducing the need for new manufacturing.