How to make a dagger – Embark on a captivating journey into the art of crafting your own dagger. This comprehensive guide will equip you with the knowledge and techniques to forge a sharp and durable blade, tailored to your specific needs. From selecting the finest materials to the intricate process of assembly, we’ll delve into every aspect of dagger making, empowering you to create a weapon that is both functional and aesthetically pleasing.

Whether you’re an experienced blacksmith or a novice eager to learn, this guide will provide you with the essential insights and practical instructions to craft a dagger that will serve you well for years to come.

Materials and Tools

Crafting a dagger requires specific materials and tools. The primary material for the blade is steel, known for its strength and durability. Wood is commonly used for the handle, providing a comfortable grip and insulation from the blade. Leather is often employed for the sheath, protecting the dagger and facilitating its carry.

Essential tools for shaping the dagger include a forge and anvil for heating and hammering the steel, a grinder for shaping the blade, and a sharpening stone for honing the edge. Additionally, a drill press, saw, and carving tools are necessary for crafting the handle and sheath.

Blade Design and Forging

Dagger blades come in various shapes, each with its advantages. Common designs include the double-edged dagger, ideal for piercing and thrusting, and the single-edged dagger, suitable for both cutting and stabbing. The choice of blade shape depends on the intended use of the dagger.

Forging the blade involves heating the steel in a forge and hammering it into shape on an anvil. This process requires skill and precision to achieve the desired shape and thickness. The blade is then tempered to enhance its strength and durability.

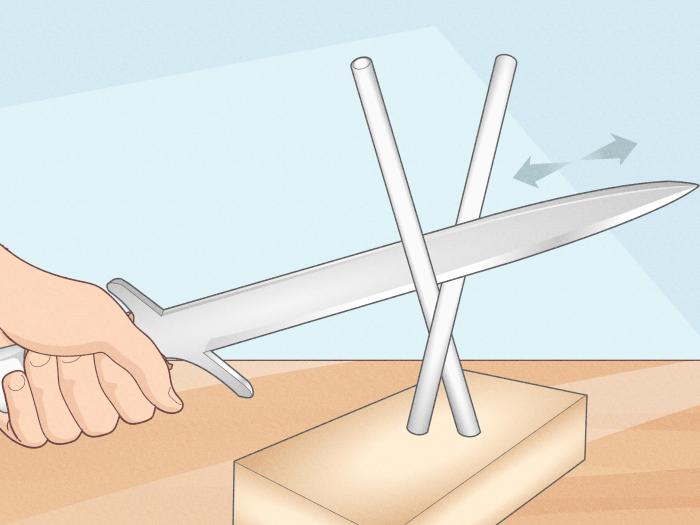

Sharpening the blade is crucial for its effectiveness. This is done using a sharpening stone, which is moved along the edge at a specific angle to create a sharp and durable cutting surface.

Handle Design and Construction

The handle of a dagger serves both functional and aesthetic purposes. It should provide a comfortable grip while ensuring control over the blade. Common handle designs include the full tang, where the blade extends through the entire handle, and the hidden tang, where the blade is concealed within the handle.

Carving and shaping the handle from wood or other materials requires precision and attention to detail. The handle is then attached to the blade using adhesives or mechanical fasteners, ensuring a secure connection.

Selecting the right material for the handle is important. Wood offers warmth and comfort, while bone or antler provides durability and a unique aesthetic. Proper treatment of the handle material, such as oiling or sealing, enhances its longevity.

Sheath Design and Crafting

A well-designed sheath protects the dagger and facilitates its carry. Materials commonly used for sheaths include leather, wood, and metal. Leather sheaths are popular for their flexibility and durability, while wooden sheaths offer protection and can be intricately carved.

Crafting a sheath involves cutting and shaping the material to fit the dagger snugly. Stitching, rivets, or other fasteners are used to secure the sheath together. A belt loop or other attachment mechanism allows the sheath to be carried conveniently.

Creating a custom sheath ensures a perfect fit and complements the dagger’s design. This requires careful measurements and attention to detail, resulting in a sheath that protects the dagger while maintaining its accessibility.

Assembly and Finishing: How To Make A Dagger

Assembling the dagger involves attaching the blade to the handle and securing it with adhesives or mechanical fasteners. The sheath is then fitted to the dagger and secured in place.

Finishing the dagger includes polishing the blade and handle to enhance its appearance and durability. Engraving or other decorative elements can be added to personalize the dagger and make it a unique piece.

Proper maintenance and care are essential to preserve the dagger’s condition. Regular cleaning and oiling prevent rust and corrosion, while sharpening the blade ensures its cutting effectiveness.

Popular Questions

What type of steel is best for making a dagger?

High-carbon steels, such as 1095 or O1, are commonly used for their strength and ability to hold an edge.

How do I achieve a sharp cutting edge on my dagger?

Sharpen the blade using a series of progressively finer sharpening stones, finishing with a honing steel to refine the edge.

What materials can I use for the handle?

Popular handle materials include wood, bone, antler, and micarta, each offering unique aesthetic and ergonomic properties.

How do I secure the blade to the handle?

Common methods include pinning, epoxy, or a combination of both, ensuring a strong and durable bond.