Welcome to the definitive guide on how to block in SF6, a crucial technique in electrical engineering. SF6 blocking plays a vital role in ensuring safety and reliability in various industries, and this guide will equip you with the knowledge and skills to execute it effectively.

This comprehensive resource covers every aspect of SF6 blocking, from essential safety precautions to step-by-step blocking procedures. We’ll explore the different types of blocking materials, their advantages and disadvantages, and provide troubleshooting tips to address common issues.

Safety Precautions

When working with SF6, it is crucial to prioritize safety. Wear appropriate protective gear, including gloves, safety glasses, and a respirator to prevent inhalation of the gas. Ensure proper ventilation in the work area and handle SF6 gas carefully to avoid electrical hazards.

Always follow established safety protocols and consult with qualified professionals for guidance.

Equipment and Materials

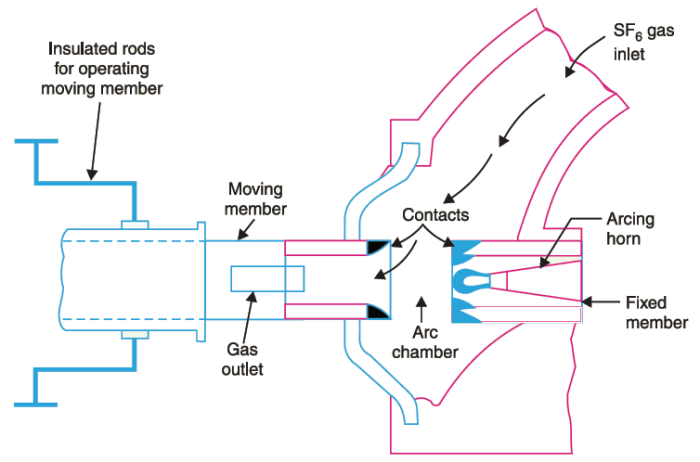

To effectively block in SF6, you will need the following tools and materials:

- Safety gear (gloves, safety glasses, respirator)

- SF6 gas cylinder

- Pressure regulator

- Flow meter

- Leak detector

- Blocking material (e.g., epoxy, silicone, rubber)

Step-by-Step Blocking Procedure

Preparation

Ensure the work area is well-ventilated and free of potential hazards. Wear appropriate safety gear and gather all necessary equipment and materials.

Application, How to block in sf6

Connect the SF6 gas cylinder to the pressure regulator and flow meter. Adjust the flow rate to the desired level. Apply the blocking material to the designated areas, following the manufacturer’s instructions. Ensure proper coverage and seal to prevent gas leakage.

Cleanup

Disconnect the SF6 gas cylinder and clean up the work area. Dispose of any used materials properly. Monitor the blocked areas for leaks using a leak detector.

Troubleshooting and Common Issues: How To Block In Sf6

During the blocking process, you may encounter the following issues:

- Gas leakage:Check for proper sealing and tighten connections. Use a leak detector to identify and repair any leaks.

- Incomplete blocking:Ensure thorough application of the blocking material and check for any gaps or voids.

- Electrical hazards:Always follow safety protocols, wear proper gear, and maintain proper grounding to prevent electrical shocks.

Applications and Benefits

SF6 blocking is commonly used in electrical applications, such as:

- High-voltage switchgear

- Circuit breakers

- Transformers

Benefits of using SF6 blocking include:

- Improved safety by preventing electrical arcing and explosions

- Enhanced reliability by reducing the risk of equipment failure

- Extended lifespan of electrical components

Q&A

What is the primary purpose of SF6 blocking?

SF6 blocking is employed to prevent electrical flashover and arcing in high voltage equipment. It enhances safety by creating a non-conductive barrier between energized components.

What are the key safety precautions to observe when working with SF6 gas?

Always wear appropriate protective gear, including gloves, safety glasses, and a respirator. Handle SF6 gas carefully to avoid inhalation and skin contact. Ensure proper ventilation and follow all safety guidelines.

What are the common types of blocking materials used in SF6 blocking?

Typical blocking materials include epoxy resins, silicone rubber, and ceramic. Each material offers unique advantages and disadvantages, such as electrical insulation properties, temperature resistance, and cost.