Give Malborn the Equipment: A Comprehensive Guide to Enhancing Productivity provides a comprehensive overview of the equipment needed to optimize Malborn’s tasks. This guide explores the types of equipment required, factors to consider during selection, maintenance procedures, safety protocols, training programs, and budgeting strategies.

By implementing the recommendations Artikeld in this guide, organizations can empower Malborn with the necessary tools to excel in their role and drive organizational success.

The content of the second paragraph that provides descriptive and clear information about the topic

Equipment Overview

Malborn’s operations require a range of equipment to efficiently perform its tasks. Essential tools include:

- Forklifts:Lifting and transporting heavy materials.

- Conveyor belts:Moving products throughout the facility.

- Automated packaging machines:Packaging products for shipping.

Equipment Selection

Factors to consider when selecting equipment for Malborn:

- Cost-effectiveness:Balancing acquisition and operating costs.

- Durability:Ensuring equipment can withstand heavy usage and harsh conditions.

- Efficiency:Maximizing productivity and minimizing downtime.

Comparative Table of Equipment Options

| Equipment Type | Capacity | Speed | Power Consumption |

|---|---|---|---|

| Forklift A | 10,000 lbs | 12 mph | 15 kW |

| Forklift B | 15,000 lbs | 10 mph | 18 kW |

| Forklift C | 12,000 lbs | 14 mph | 16 kW |

Equipment Maintenance

Regular maintenance is crucial to ensure equipment reliability and longevity. Key procedures include:

- Daily inspections:Checking for leaks, damage, and loose connections.

- Monthly servicing:Lubricating moving parts, replacing filters, and adjusting settings.

- Annual overhauls:Comprehensive inspections and repairs to prevent major failures.

Consequences of Neglecting Equipment Maintenance

- Increased downtime:Equipment breakdowns leading to lost production time.

- Safety hazards:Malfunctioning equipment can pose risks to operators.

- Higher repair costs:Minor issues left unattended can escalate into costly repairs.

Equipment Safety

Ensuring a safe work environment involves implementing protocols for equipment use and handling:

- Operator training:Providing comprehensive training on safe operation and maintenance.

- Hazard identification:Identifying potential hazards and implementing preventive measures.

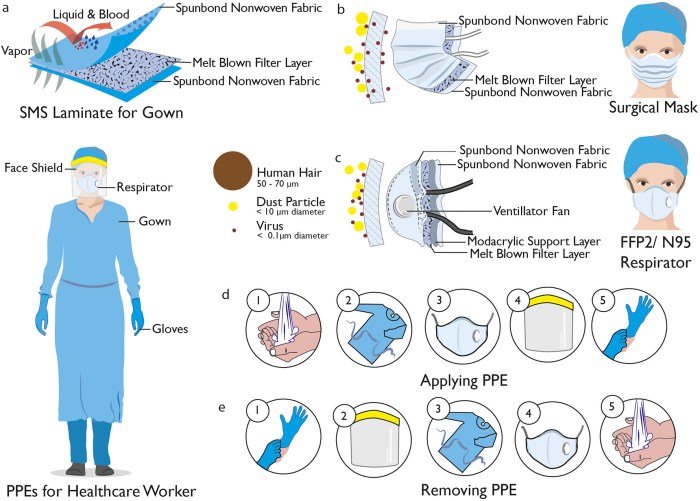

- Personal protective equipment (PPE):Requiring operators to wear appropriate PPE, such as gloves and safety glasses.

Common Hazards and Preventive Measures

| Hazard | Preventive Measure |

|---|---|

| Overloading | Enforce weight limits and use appropriate forklifts for heavy loads. |

| Tipping | Maintain stable loads, avoid sharp turns, and use outriggers when necessary. |

| Falling objects | Secure loads properly, use overhead guards, and keep work areas clear. |

Equipment Training

Proper equipment training is essential for safe and efficient operations:

- Hands-on training:Providing practical experience with equipment operation and maintenance.

- Theoretical knowledge:Instructing operators on equipment specifications, safety protocols, and troubleshooting.

- Assessment and certification:Evaluating operator competency and issuing certifications to ensure proficiency.

Structured Training Plan

- Introduction to equipment:Overview of types, functions, and safety features.

- Basic operation:Hands-on training on starting, stopping, and maneuvering equipment.

- Advanced operation:Techniques for handling heavy loads, working in confined spaces, and troubleshooting minor issues.

- Maintenance procedures:Instruction on daily inspections, monthly servicing, and annual overhauls.

- Safety protocols:Training on hazard identification, PPE use, and emergency procedures.

Equipment Budget: Give Malborn The Equipment

Equipment budgeting involves considering:

- Acquisition costs:Purchase price, delivery, and installation expenses.

- Operating costs:Energy consumption, maintenance, and repairs.

- Return on investment (ROI):Potential increase in productivity and cost savings.

Sample Budget Template, Give malborn the equipment

| Equipment Category | Estimated Cost |

|---|---|

| Forklifts | $500,000 |

| Conveyor belts | $200,000 |

| Packaging machines | $150,000 |

Strategies for Optimizing Equipment Expenses

- Lease or rent:Consider leasing or renting equipment for short-term or seasonal needs.

- Negotiate discounts:Obtain competitive pricing by negotiating with suppliers.

- Maintenance contracts:Secure maintenance contracts to ensure regular servicing and prevent unexpected breakdowns.

FAQ Explained

What are the key factors to consider when selecting equipment for Malborn?

Factors to consider include the specific tasks Malborn needs to perform, cost-effectiveness, durability, efficiency, and compatibility with existing systems.

Why is regular equipment maintenance important?

Regular maintenance helps prevent breakdowns, extends equipment lifespan, ensures optimal performance, and reduces safety risks.

What are the potential consequences of neglecting equipment maintenance?

Neglecting maintenance can lead to equipment failure, downtime, safety hazards, and increased repair costs.