The Dead Space Plasma Cutter is a remarkable tool that has revolutionized the cutting industry. Its unique design and advanced technology set it apart from other plasma cutters, making it a preferred choice for various applications.

With its ability to cut through a wide range of materials with precision and efficiency, the Dead Space Plasma Cutter has become an essential tool for metalworkers, fabricators, and artists alike.

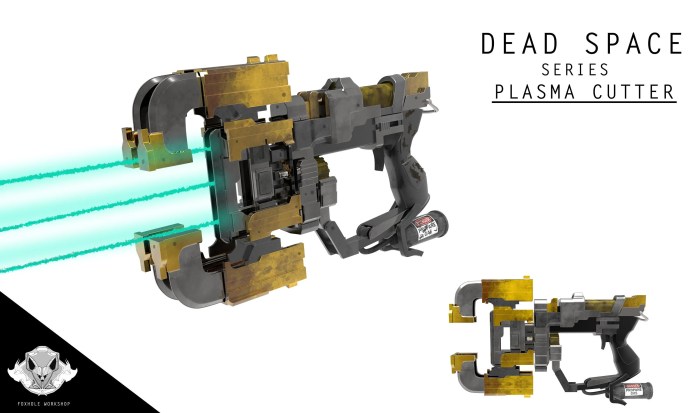

Overview of Dead Space Plasma Cutter

The Dead Space Plasma Cutter is a versatile and iconic tool in the Dead Space video game series. Originally developed by EarthGov for industrial mining operations, it has become a mainstay for Isaac Clarke, the protagonist of the series, as he battles grotesque alien necromorphs.

Its unique design features a compact and lightweight body, making it easy to maneuver in tight spaces. The cutter’s distinctive serrated blade is made of a highly durable alloy that can cut through various materials with precision.

Functionality and Mechanics

The Plasma Cutter operates on the principles of plasma arc cutting. It uses a high-voltage electrical current to ionize a gas, typically argon or nitrogen, creating a plasma arc. This arc is then directed through the nozzle and onto the workpiece, melting and vaporizing the material.

The Plasma Cutter offers various modes and settings to adjust the power and shape of the plasma arc. This allows for precise cutting of different materials and thicknesses.

Applications and Usage

The Plasma Cutter is widely used in industrial settings, particularly in metal fabrication, shipbuilding, and automotive repair. It is also employed in artistic metalworking and sculpture creation.

The cutter’s ability to cut through metal, wood, and plastics makes it a versatile tool for various applications, including cutting sheet metal, welding preparation, and removing rust and corrosion.

Comparison with Other Cutting Tools

Compared to other cutting tools, the Plasma Cutter offers several advantages. It provides faster cutting speeds than water jets and is more versatile than laser cutters, as it can cut through a wider range of materials.

However, Plasma Cutters may produce more dross and heat than laser cutters, and they require more safety precautions due to the generation of plasma gas and molten metal.

Maintenance and Troubleshooting, Dead space plasma cutter

Regular maintenance is crucial for the longevity and performance of the Plasma Cutter. This includes cleaning the nozzle and electrodes, inspecting the cables and hoses, and replacing consumables such as tips and shields.

Common troubleshooting techniques involve checking for proper gas flow, ensuring good electrical connections, and addressing overheating issues.

Customization and Accessories

Various accessories and attachments can enhance the Plasma Cutter’s functionality. These include specialized tips for different materials, nozzles for adjusting the plasma arc shape, and guides for precise cutting.

By customizing the Plasma Cutter with appropriate accessories, users can optimize its performance for specific applications.

FAQ Resource

What are the advantages of using a Dead Space Plasma Cutter?

The Dead Space Plasma Cutter offers several advantages, including its ability to cut through various materials with precision, its ease of use, and its portability.

What are the different modes available on the Dead Space Plasma Cutter?

The Dead Space Plasma Cutter features multiple modes, including a precision mode for intricate cuts, a speed mode for faster cutting, and a power mode for cutting through thicker materials.

How do I maintain my Dead Space Plasma Cutter?

Regular maintenance is crucial for the longevity and performance of your Dead Space Plasma Cutter. This includes cleaning the unit, inspecting consumables, and replacing them as needed.