How do you make stone? This intriguing question unveils the fascinating world of stone creation, where natural forces and human ingenuity intertwine to produce a material of timeless beauty and enduring strength. From the depths of quarries to the precision of manufacturing plants, this article delves into the intricate processes that transform raw materials into the stones that shape our built environment and inspire artistic masterpieces.

Throughout history, stone has played a pivotal role in human civilization, serving as a foundation for structures, a canvas for sculptures, and a symbol of cultural heritage. Understanding the methods and properties of stone empowers us to appreciate its versatility and make informed choices when incorporating it into our designs and creations.

Types of Stone: How Do You Make Stone

Stone is a versatile material used in a wide range of applications, from construction to landscaping to art. There are many different types of stone, each with its own unique properties and characteristics.

Natural stone is formed by the Earth’s geological processes over millions of years. It is composed of minerals such as quartz, feldspar, and mica. Natural stone is durable and long-lasting, making it a popular choice for construction and landscaping.

Manufactured stone is created by combining aggregates such as sand, gravel, and cement. It is a more affordable option than natural stone, and it is available in a wide range of colors and textures.

Composite stone is a combination of natural stone and manufactured stone. It is typically made from a mixture of stone dust, resin, and pigments. Composite stone is durable and easy to maintain, making it a popular choice for countertops and other interior applications.

Methods of Stone Creation

Natural stone is quarried from the Earth’s surface. Quarrying involves using explosives or heavy machinery to break the stone into smaller pieces. The pieces are then transported to a processing facility, where they are cut and shaped into blocks, slabs, or tiles.

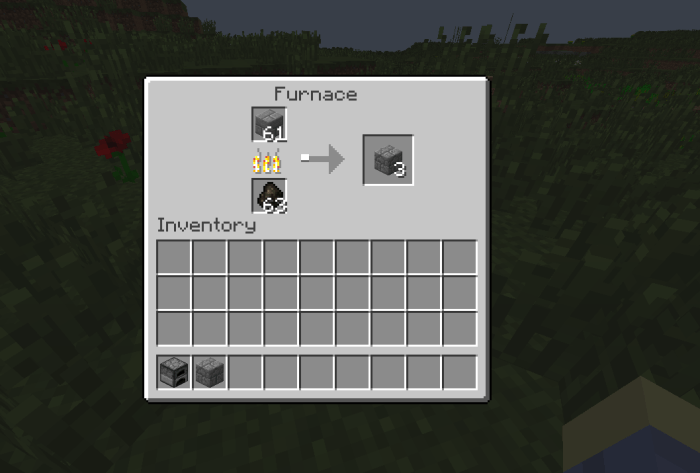

Manufactured stone is created by mixing aggregates such as sand, gravel, and cement. The mixture is then poured into molds and allowed to cure. Once the stone has cured, it is cut and shaped into blocks, slabs, or tiles.

Composite stone is created by combining natural stone and manufactured stone. The mixture is then poured into molds and allowed to cure. Once the stone has cured, it is cut and shaped into blocks, slabs, or tiles.

Properties of Stone, How do you make stone

The properties of stone vary depending on the type of stone. However, some of the most important properties include:

- Density: The density of stone is a measure of how much mass it has per unit volume. Dense stones are more durable and resistant to wear and tear.

- Hardness: The hardness of stone is a measure of how resistant it is to scratching. Hard stones are more durable and resistant to wear and tear.

- Porosity: The porosity of stone is a measure of how much water it can absorb. Porous stones are more susceptible to staining and weathering.

- Durability: The durability of stone is a measure of how well it can withstand the elements. Durable stones are more resistant to wear and tear, and they can last for many years.

Applications of Stone

Stone is used in a wide range of applications, including:

- Construction: Stone is used in a variety of construction applications, including foundations, walls, and floors. It is also used to make countertops, tiles, and other decorative elements.

- Landscaping: Stone is used in a variety of landscaping applications, including patios, walkways, and retaining walls. It is also used to make sculptures, fountains, and other decorative elements.

- Art: Stone is used in a variety of art applications, including sculptures, paintings, and mosaics. It is also used to make jewelry, pottery, and other decorative objects.

Sustainability of Stone

The quarrying and manufacturing of stone can have a negative impact on the environment. However, there are a number of efforts being made to reduce the environmental footprint of stone production.

One of the most important efforts is to reduce the amount of waste generated during the quarrying and manufacturing process. This can be done by using more efficient cutting and shaping techniques, and by recycling waste materials.

Another important effort is to reduce the amount of energy used during the quarrying and manufacturing process. This can be done by using more energy-efficient equipment, and by using renewable energy sources.

Finally, it is important to promote the use of sustainable alternatives to natural stone. These alternatives include recycled stone, composite stone, and concrete.

Answers to Common Questions

What are the different types of stone?

Stone can be broadly categorized into natural stone, manufactured stone, and composite stone. Natural stone is formed through geological processes over millions of years, while manufactured stone is produced by combining aggregates, such as crushed stone or recycled materials, with a binding agent.

Composite stone, on the other hand, is a blend of natural stone and other materials, such as glass or resin.

How is natural stone quarried?

Natural stone quarrying involves extracting stone blocks from the earth using specialized equipment and techniques. The process typically begins with identifying and surveying the stone deposit, followed by removing overburden and using drilling and blasting to extract the stone blocks.

What are the key properties of stone?

Stone possesses a range of properties that influence its suitability for different applications. These properties include density, hardness, porosity, compressive strength, and resistance to wear and weathering.